Led strips with lighting performances of 100, 140 and even 180 lumen per watt have increasingly gained popularity on the market. Since the heat levels generated by these led strips are very high, the lifetime of the led will shorten, unless we use a better heat dissipation system.

By correctly designing a led profile, we can enhance its heat dissipation ratings up to 30% more when compared to a non-optimised profile, which has the same aluminium content.

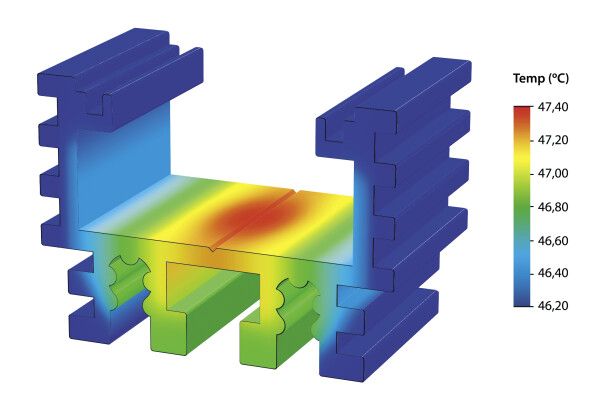

Optimum ventilation through thermal conduction (therefore implying the highest values of absorption of the heat generated by the led) will be achieved with the led profile by settling a balance between the amount of aluminium covered by the profile and the geometry of its design. On the matter of design, protruding surfaces and channel-shaped areas are elements of utmost importance in order to avoid resistance against the distribution of thermal energy.

When our led profiles are being designed, these and other issues such as, for instance, accuracy of the finishes are taken into account (an anodising process will always provide higher levels of stable heat dissipation to the profiles when compared to a lacquering process). By doing so, we manage to achieve functional profiles, which are also competitive in terms of pricing.

thermal dissipation

thermal dissipation

| Ref | Description | ||

|---|---|---|---|

| 46.063 | THERMAL DISSIPATION TESTING | See price |

|